Significance of Bending Test Fixtures

Flexural goods are examined by testing a material using a 3 or 4 point bend fixture. These bend fixtures have 2 support spans and one or two loading nose points on top. Most three point SSAT flex tests require that the third loading point be centered on the sample.4 point tests require that the 2 top loading points bisect the sample into thirds or fourths.

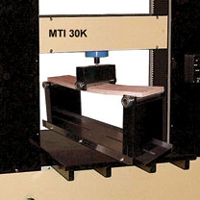

3 point Bend Fixtures

Three point Bending Test Fixtures use center loading to bend the sample. The 3rd point bending text is connected directly to the top arm of the universal testing machine by use of a clevis pin adapter. The bottom two pillars are adjustable and can integrate samples of different length. The coextensive gear start custom bend fixture is a nice solution if you are changing between multiple specimen sizes.

4 Points Bend Fixtures

Four point

flexural Bending Test Fixtures have two base supports and two top

loading points, where the load contact points are on the sample. The first type

splits the sample into three parts. The second test divides the sample into

four parts.

Support Span and Loading Noses

The

space of the contact points is important

and this measurement is usually specified in the relevant MTI test overview.

The standard radius tends to be 5mm. The

bottom spans on maximum jigs are

amendable, so they actually have two usable radii.

Adjustable and Interchangeable Rollers:

Interchangeable

Rollers permit the bend fixture to have

much more utility in terms of the contact radius. Small rubber O-rings are used

to fix the roller into place.

Anti- Roll Technology

The medium

and larger size bend fixtures can be furnished

with an anti-roll retaining bar which stops the sample from rolling or

buckling during compression.

Comments

Post a Comment